10 Flow Meter Types & Their Function

As manufacturing units and production houses need to have multiple lines of production running simultaneously then it becomes difficult to measure flow rates and flow velocity accurately and effectively.

Various flow meter types (the devices to measure the flow rates and flow velocity) play a pivotal role optimizing those production lines in single by maintaining, measuring, and monitoring supply pressure and flow rate of fluid flowing through those pipes and tubes.

What is a Flow Meter?

Flow Meters are instruments used by industries like water mater management agencies, oil & gas industry, energy production firms, pharmaceutical, and fire hydrant testing to measure the flow rate at which fluids (liquids, gases, and vapors) flow in a pipe.

Industries like chemical processing, water treatment, pharmaceutical, food and beverages, or power generation plants, fire hydrant testing companies, all are using flow meters to derive efficiency in measuring and monitoring flow of fluids (gases, liquids, or vapors).

We, New England Manufacturing have been in the market, dealing in all kinds of flow testing accessories, for the last 100 years and building a legacy of quality for the future. Whether you need a hydrant flow nozzle, pressure gauges, or a full and customized water flow kit, you can find a huge and wide range of products with the best quality.

Where are flow meters needed in industries?

All types of manufacturing units and industries of different sectors are using various kinds of flow meters to measure, monitor, detect possible leakages and breakages, and take actions in advance to curb accidents and ensure accuracy and efficiency.

Particularly, gas & oil companies, water management companies, fire hydrants testing firms, drug manufacturing units, etc. These are heavily dependent on different flow meter types to run their daily operations smoothly.

10 Flow Meter Types And Their Functions

There are various kinds of flows used in various industries depending upon the type of fluid (liquid, gases, or vapor). Let’s talk about 10 flow meter types and their functionalities in detail one by one.

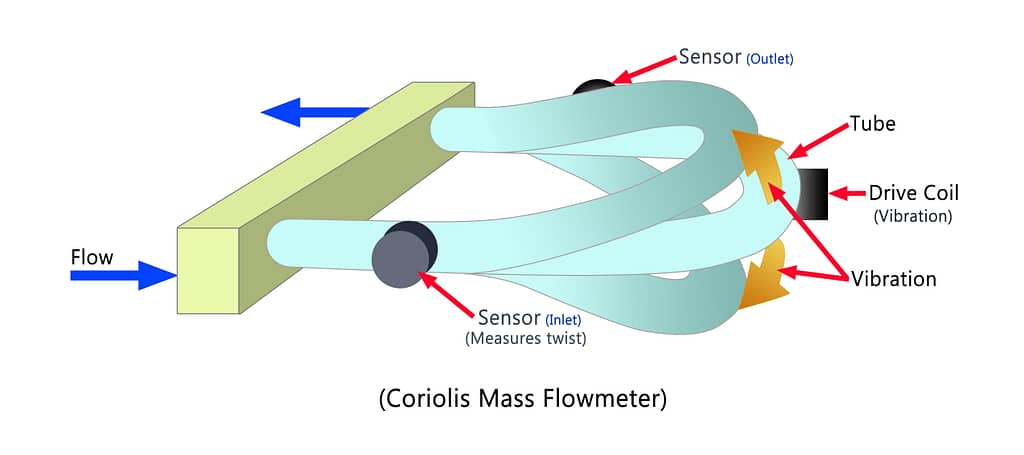

1. Coriolis Mass Flow Meter:

When the fluids have heavy mass and volume measurements are insufficient to calculate coriolis mass flow meter comes into the picture. This instrument is the best for optimal outcomes when it comes to safety in fire hydrants, gauges in water management plants or any chemical manufacturing unit.

The characteristics and functionalities of coriolis flow meter

Coriolis Effect: Primarily this device uses the coriolis effect while determining the mass of the fluid along with the flow rate and flow velocity. However, the additional advantage is that you can keep a track of flow rate when the density of the fluid changes along the path in real time.

Process: When the fluid passes through the vibrating pipe or tube, a twisting motion is caused in the fluid due to the effectiveness of Coriolis force. These twists are monitored and measured by the sensor embedded in the device to calculate the accurate mass flow rate of that fluid.

You can consider a ‘rotating frame’ for understanding and simplification purposes. While these frames are in motion, fluid is induced (irrespective of the temperature and density) through them and the inertia of the fluid is acted upon by the vibrations generated in the pipe. That particular phenomena determines the to the point mass flow velocity and flow rate regardless of any change in the temperature or density of the liquid, gas, or vapor.

Quantify the nature of substance: The capabilities of coriolis flow meter are not limited to measuring flow velocity and flow rate but it has the capacity to qualify the nature and texture of the substance (gas, liquid, or vapor) flowing through the pipe or tube.

Highest Precision and Accuracy: Coriolis mass flow meters are perfect when it is about precision and accuracy as they are commendable here. As impressive as +-0.1% that too with more than 100:1 turning down ratio.

Industries and manufacturing units rely on this flow meter type mostly.

Complexities with coriolis mass flow meters: As seen above this flow meter type is quite indispensable and very crucial in processes, and considered one of the best in the market. Still there are a few complexities with this device.

For instance:-

- If there is bubble formulation in the liquid, that could lead to mis-leading in outcomes and variations in readings required for setting objectives with precision.

- Shift in temperature, sometimes affects the reliability of the outcomes and may impact the sensitivity of the data drawn.

- Structures like unobstructed piping are required to get dependable flow meter readings as these pipes are prone to stretching prior to installing and electrical grounding them.

- Industries like chemical production, food and beverages, etc. are using coriolis flow meters when they use a variety of fluids and need to determine their qualities and flow velocities separately.

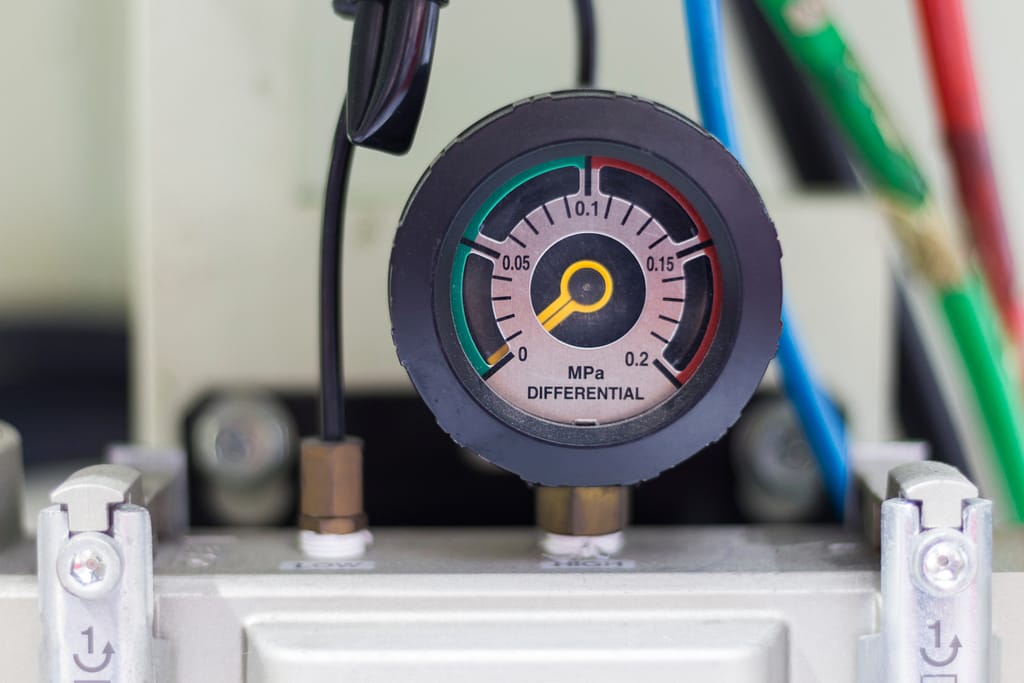

2. Differential Pressure Flow Meter Type

Differential pressure flow meter type is the most used and referred for measuring the flow rates and flow velocity. Fire hydrant testing is very much dependent on flow meters and water pressure gauge to get accurate and reliable data readouts.

Need of the hour: Differential pressure flow meter is used by over 50% of industries in the market at present. Now, it reflects the accuracy, reliability, and dependency on this particular device. These flow testing devices and various industries.

Principle of differential pressure flow meter: The basis principle (Bernoulli’s Principle) behind the premises that the pressure of the fluid flowing through the pipe or tube drops across the meter is directly proportional to the square area of the flowing floor.

Advantages of using differential pressure flow meter:

Here are some of the top characteristics of this flow meter type because of that it is being chosen widely.

- When the space to fit in the devices is small and requires minimal piping, then this is the best option to choose.

- Measuring flow rate of fluids flowing under high temperature conditions and different fluid types, then this flow meter type proves to be the best.

- For non-conductive fluid (liquids) like electromagnetic counterparts, which is a very challenging task, this flow meter makes it possible to measure flow rate and flow velocity.

- Can embed averaging pilot tailored elements in the pipe and moving velocity.

-Calculation of flow rate in differential pressure flow meter:

Formula;

Differential pressure flow rate = Pressure difference / Gravity of the fluid

Then,

Square root of = (Pressure difference / Gravity of the fluid)^2

Then,

Differential pressure flow rate (Q) = (Pressure difference / Gravity of the fluid)^2 *Flow Factor (Kv)

Q = √(Kv² × (ΔP/S))

Process: There are two functions of differential pressure flow meter like all flow meter types, primarily element in the meter assists in changing energy to kinetic energy that helps in creating differential pressure in the fluid flowing medium (pipe and tube).

And the secondary element in the flow meter is responsible for measuring differential pressure and data in the form of read-outs on the screen of the meter and eventually converting the read-outs to flow rates.

However, the accuracy of the actual units of final flow rates depends upon the size of the pipe, conditions under which fluid flows, properties of the fluid (liquid, gas, or vapor). And should consider a good range of area and distance for getting the maximum accuracy and optimal outcomes.

Abide by ISO 5167: Majority of industries, manufacturing units, energy plants, pharmaceutical firms are depending on differential pressure (DP) flow meters for measuring, monitoring the flow rates because it abides by ISO 5167.

3. Volumetric Flow Meter Type:

So far we have talked about pressure and mass based flow meter types. What if the substance nature is of kind where mass and pressure measurements are not possible.

Then comes volume-based flow measuring flow meters. Now, let’s look into one such flow meter type – Volumetric Flow Meter.

Volumetric flow meters are used to calculate and measure fluid speed and fluid velocity in a pipe.

Flow meters like positive displacement, ultrasonic, turbines, vortex, and electromagnetic flow meters all are closely and remotely related to each other. These all are designed to gauge flow rate by applying their unique principles they operate on.

Purpose of volumetric flow meter: These meters are virtuous in determining accurate velocity and precise flow rate of the fluid. Its impressive dexterity is very reliable for volume-based-assessment.

Innovative and advancement: Volumetric flow meters have gone under immense innovations and revolution over the time like addition of novel sensing techniques, technological modifications, calibration methods, etc. taking these flow meters to another level of precision and efficiency.

-Overcomes short-comings of displacement pressure flow meter: Volumetric flow meters have rangeability (the range of flow in a pipe where a flow meter is able to measure flow rate with precision, also known as turndown ratio. This is one of the most crucial and essential elements to be kept in mind while finalizing the choice of flow meter to eb used).

Rangeability enables these flo meters to excel in getting optimal, accurate, and reliable readouts at the time of measurement.

If pressure drops, pressure and mass based flow meters may not be able to yield the best results, but volumetric flow meters become the ultimate partner.

Distinct and advanced traits of volumetric flow meter like versatility, various setting modes, revolutionised turbine blades, etc. have distinguished these meters as heady and operationally reliable in the market.

All these characteristics enable them to suit various conditions. Whether fluids flow irregularly through the pipe or quantity differs from time to time, still you would get consistent, reliable, accurate, and precise results here.

4. Ultrasonic Flow Meters:

Ultrasonic flow meters are redefining the ways to measure flow rates as these are prone to negligible mechanical degradation. The core reason for making them selective is they do not have moving parts in them, completely dependent upon waves and sound.

Groups of ultrasonic flow meters: Ultrasonic flow meters have two core groups – Time of Travel or Transit Time flow meter and Doppler flow meter.

1. Time of Travel (Transit Time) : This device is responsible for determining the time differences between the sonic pulses while they are in the motion (upwards or downwards) in the flowing medium (pipe or tube).

These are equipped to perform best when operating in cleaner fluids (liquids particularly) like water treatment plants, oil and gas companies, etc.

2. Doppler : These advanced instruments are responsible for reflecting sound waves from the particles of the substance (gas bubbles or liquid) flowing in the pipe.

These flow meters are well suited for measuring flow rates (flow velocity) of fluids having carbonated or aerated qualities or freely moving particulars of solids. For example – sewage treatment plants.

Factors affecting functions of ultrasonic flow meter type:

Here are some of the top characteristics and functions of this flow meter type, let’s have a look at them.

- Temperature: As the temperature fluctuates in the fluid, there may be some changes in the readouts on the screen of the flow meter.

- Variable Density: This factor should be considered carefully as it may modulate the measurements of the flow meter.

- Viscosity Change: Measurement of ultrasonic flow meters vary as a result of changes in viscosity.

- Amount of suspended solid: Presence of suspended particles in the fluid also impacts the measurements of the flow meter.

However, the solution to all these influencing factors could be minimized and controlled by a clamp-on model. Ensures accurate measurement by gauging fluid flow with clamp with minimal or zero disturbance and modifications.

Wide range applicability: Ultrasonic technology used in these flow meters assist in quantifying fluid (liquid) motion and providing a wide range of operational capability with different types of fluids.

5. Velocity Flow Meter (Vortex Flow Meter)

Mass-based flow meters, volumetric-centric flow meters, and differential pressure based flow meters have been talked about so far. Now, let’s get into the details of how velocity is used in flow meters, and how speed of the fluid becomes the determining factor.

Process: While the fluid is moving in a pipe or a medium, velocity flow meter records speed (velocity) of the fluids at multiple points for a time period over the area of flow.

Then those measurements are presented in the form of graphs and strokes. Eventually, derive flow rate of the fluid by integrating those strokes for that particular time period.

Adaptability: Performing under different temperatures and varied pressure make them adaptable and suitable to use.

Example: Vortex and turbine flow meters are the leading ones in this specific category of flow meter types.

Vortex flow meters are primarily used in water management, chemical plants, and oil and gas companies. While turbine flow meters are highly used in petroleum based fluids.

Characteristics and features of velocity flow meter:

- No impact of viscosity change: These flow meters are so apt that even when there is viscosity change in the fluid flow, there is no significant change in the outcomes and readouts.

- Highest accuracy: Even under non-linear flow and low-viscosity liquids, velocity flow meters are considered as first choice as they provide the highest quality, precision in measurements, and reliable outcomes.

- Easy to install: Velocity flow meters require minimum time and space to get installed and start functioning.

- Integration with pipeline: Are directly integrated with the pipeline (like gas pipeline in households or factories) without actively gauging daily manually to calculate fluid speed and flow rate.

Velocity flow meters are easy to adapt, install and measure flow rates and velocity, hence are chosen by users frequently.

6. Open Channel Flow Meter

Let’s move to the direction where gravity plays a crucial role in determining the flow rates. Yes, that is possible through open channel flow meters where no artificial force is required to measure the rate and velocity of flow of a fluid.

As the name suggests, the systems are open (non-contained) and open channel flow meter type has proven to be one of the most dominating flow meters in terms of advancement, vastness of applicability, and reliability of readouts.

Process: Open channel flow meters have level sensors, deployed in them. That identifies the level of fluid (liquid, fluidized solid, granular level substances, powder material having upper free surface, or slurries) without even making any contact with the fluid.

Measuring flow rate of the fluid by tracking the liquid movement without any constraint contact. Used mainly in channels, weirs, pipes not filled completely, and flumes.

Sensor usage: Ultrasonic sensors are used in open channel flow meters, these sensors detect the depth and the structure of the water body to calculate upward and downward flow movement of the fluid (water).

Modbus RTU (Remote terminal Unit): Modbus RTU (a digital protocol and binary implementation of Modbus) uses a series of communications to establish connection between the devices. This is a reliable way to data storage as it is well known for its effective data representation and efficiency.

Smooth integration with natural elements: The smooth implementation into different applications to calculate, measure, and monitor flow rates shows how flawlessly open channel flow meters are ready to integrate with natural phenomenons and yield effective, accurate, transparent, and durable results.

However, there could be inconsistency in calculations if the flow of the fluid is not constant and fluctuates in between.

7. Electromagnetic flow meters (Magmeter):

Electromagnetic flow meters, also known as magmeters, are designed on the principles of electromagnetic induction. Measures, monitors, and regulates flow rate of electrically conductive fluids (liquids or semi-liquids).

Process: Electromagnetic flow meters are embedded with coils (generating magnetic field) and electrodes in a non-intrusive flow pipe (tube).

Once an electromagnetic flow meter is active, fluids are run through that magnetic field generated. Then voltage exactly proportional to the flow rate is introduced. That eventually, calculates the flow rate using electrodes.

Make sure you are not leaving any air bubbles while installing the flow meter to the pipe for accurate and optimal outcomes. Because there are possibilities of error in measurement by 0.5% to the actual flow rate if installation was inappropriate or air bubbles were created.

Measures flow in both directions: Yes, electromagnetic flow meters are capable of measuring flow rates in both directions, that’s why it is demanded relatively higher than other flow meters across different sectors and industries.

-Used by multiple sectors: Industries like water management plants, paper production units, chemical processing companies, metallurgy sector, etc. are using electromagnetic flow meters to measure flow rates accurately and effectively.

-Limitations of electromagnetic flow meter: Despite being one of the majorly demanded flow meters in the market and various sectors, this flow meter does have a few boundations for applicability.

- Suitability: Electromagnetic flow meters can be applied for measuring flow rate of fluids having electrical conductivity.

- Not applicable universally: Not applicable in sectors not using electromagnetic fields or electronic induction in their operations.

- Maintenance issue: If the separation of flow meter from the model should be done with optimal carefulness otherwise could cause maintenance issues later.

Other than that electromagnetic flow meter is effective, user-friendly, yields accurate results, and reliable for storing data.

8. Positive displacement flow meter

Positive flow meter measures are significantly used in many sectors and are usually known for its systematic fluid flow rate measurements approach.

Process: Positive displacement flow meters function differently than all the above mentioned flow meters so far. Here small volumes of fluid (liquid) are trapped in small chambers created within the device. Then these chambers are cycled then released and you get the results (flow rate of the fluid used in the chambers).

While operating through this flow meter type, ensure that every time the chambers are filled and released with fluid in complete isolation until the measurements are done to get accuracy and reliability on the readouts.

Positive displacement flow meter types: There are many types of positive displacement flow meters in the market. However their usage and application depends upon the nature of fluid and sector using it. Some of the flow meter types include gear meters, oval gear meters, nutating disk meters, and piston meters.

These all flow meters are unique and use different mechanisms to gauge and measure volume of fluids flowing through them at the given time.

Inter-dependence and inter-relatedness: For instance, helical gears engage within a helix gear meter or interlocking oval shape gear performing in a simple oval gear meter, when required but the circumstances and requirements decide that.

Purpose: Positive displacement flow meters are designed particularly for viscous liquids, clean gases, or charged liquids. Some of their usages include heating lubricants and oils, heating polymer additives, etc.

Accuracy: Accuracy up to 0.1% full scale reading is claimed by these flow meters, and turn down ratio under this flow meter more than 70:1. These incredible features and capabilities make them one of the most demanding and trusted devices.

These instruments are incredible to use and rely on for accuracy. However, require high maintenance checks and frequent calibrations to deliver best performance and yield accurate measurement.

Also, keep in mind that, liquid nature and other factors can result in altering the operational efficiency drastically.

9. Pitot tube flow meter:

Pitot flow meter is the simplest flow meter device and quite easily available in the market. However, they have small scale applicability depending upon the nature of the fluid (liquid) in the pipe.

Pitot tubes are gauged in the fluid carrying pipe (tubes) by welding a coupling in it. Then through that the device is inserted through that in the flowing fluid through the pipe.

Single point measurement: Measuring flow rate using pitot flow meter is simple as it can be calculated using a single measuring point on the pipe.

Sensitive to change: The outcome of the pitot flow meter is quite sensitive to outside factors and change in the environment around the fluid.

Advantages: These flow meters are very cost effective, no moving parts required, super easy to install, and go through minimum drop in pressure during measurements.

10. Orifice Flow Meter

Orifice flow meters are one of the most demanded, trusted, and popular flow meter types in the market at present. A metal piece with a hole in it is used in this meter to measure the flow rate of liquids.

Are available in eccentric form, in segmental structures, and conical shape (quadrant), however the most used one is concentric design.

Process: The orifice plate (a metal piece with a hole in it) is embedded between two parallel brims. As the fluid passes through the orifice plate, differential pressure is generated across the metal piece.

Then the pressure recorder at each side of the orifice plate is used to identify the difference and determine the flow rate (flow velocity).

Advantages: One of the most crucial advantages is that they do not need moving parts for installation and operation and are cost effective as there is no cost addition as the size of pipe increases.

Accuracy: Flow rate of orifice flow meter primarily depends upon orifice area ratio, conditions of installation, liquid properties (physical and chemical both of the liquid being metered).

Orifice flow meter is very easy to install as no special pipe or no particular fitting is required to install the same. And measures the flow rate with ease without complexities. Hence a user friendly device (flow meter).

Conclusion

Flow meters are needed by different sectors, industries, and companies based on their requirements. And there many flow meter types in the market, each flow meter type has their advantages, a few potential drawbacks, and ideal applications for each type of flow meter, that optimizes your operation’s performance.

Pharmaceutical companies, oils and gas plants, chemical units, water treatment plant and water management (handling) companies, etc. are using flow meters in their daily operations to have operational efficiency, breakage and leakage identification, error detection, and taking corrective actions accordingly.

Mark R.

With a strong foundation in industrial safety and fire protection systems, Mark R. specializes in creating clear, technical, and compliance-driven content. Writing for SafeTech Reports, he covers topics such as fire hydrant testing, PPE protocols, emergency procedures, and smart technology integration in safety systems. His work ensures that professionals stay informed on the latest regulations, best practices, and emerging trends in safety and infrastructure maintenance.

Get in touch

We usually respond within 24 hours

Need Reliable Water Flow Test Equipment?

For over 70 years, New England Manufacturing has been the trusted source for fire hydrant and water flow testing kits. From pitot gauge kits to custom test kits, we provide precision, durability, and expert calibration to meet your needs.

- Custom-built test kits

- High-quality pressure gauges

- Reliable calibration services