What is the Flow Meter Usage?

Flow meter: what is it?

Flow Meters are devices used by industries, water mater management agencies, oil & gas industry, energy production firms, pharmaceutical, fire hydrant testing etc. to measure the rate at which fluids and gases (vapors) in a pipe. Flow meter is also known as a ‘flow sensor’ and it measures all sorts of flows whether linear or non-linear flowing through a pipe during a particular period of time.

Through flow meters experts and manufacturers are able to get exact measurements of flow (oil, gas, or vapor) and monitor the same with accuracy.

New England Manufacturing has been delivering the best quality of flow meters since mora than a century. Whether pressure gauges, bleeders, or complete water flow kit, they provide top-notch experiences to customers through their products.

Why is Flow Meter used?

Industries and manufacturing plants are required to measure the flow velocity and flow rate at which fluids (liquids, gases, steams) used by them move in a tube, pipe, or conduit. Along with that monitoring, integrating, automating, and optimizing their production at a given time is essential.

Flow metres are those assisting keys to lead towards enhancements, efficiency, accuracy, and optimal production by measuring flow rate and quantity at each stage, to help detecting in advance if any leakages or breakage.

Majorly these industries use flow meters:

As mentioned above, a flow meter is a multi purpose equipment used in different industries and manufacturing units. Let’s take a closer look at some of them.

1. Water management- Water flow meter usage is quite diversified, beginning with tracking water usage in households, commercial buildings, to industries. Perfect water billing, water treatment, managing rain-water (storm water), identifying water leaks, etc. all are efficiently and accurately done because of flow meter usage by them.

- There are many types of water flow meters, depending upon the load, requirements, and level of flow, these are chosen and used. Below stated are a few types of used around us.

- Electromagnetic: Majorly used in water distribution companies to measure the control and monitor flow and pressure under control under the process of distribution.

- Clamp-On Ultrasonic: Agin, this type of meters are also used in water distribution activities to control and

- Turbine: Water Treatment plants use preservatives and additives to treat and purify water, turbine flow meters are primarily used there.

- Coriolis: Coriolis is capable of measuring flow rates at a speed of 120,000 lbs/minute (pounds per minute), used to measure mass flow of liquids and gases. Also known as an inertial flow meter and a good device to monitor density and temperature of flow.

- Positive Displacement: When water flow is low and steady, positive displacement is the best type of flow meter in the market.

2. Oil & Gas Industry: Oil and Gas industry has heavy flow meter usage. Some of the gases are highly inflammatory and toxic, ensuring they are monitored in real time, tracked properly, and detecting any leakages is crucial in the process of production and transportation.

Crude oil flow, refined products in a refinery, entire refining procedure, natural gases flow, and eventually the storage of the same need to be handled with vigilance, safety, and immense causation. That is where these supply pressure gauges and flow meters come into play to regulate and monitor the same.

In a typical oil and gas production unit, some of the core functionalities of flow meter are as such;

- For Wellhead Monitoring: How to measure the oil production at a particular point of time and the amount of waste generation happening throughout that process, falls under wellhead monitoring.

- Optimizing Production: Flow meters assist in determining the amount of stream to be released in an oil well to extract the maximum amount of oil and gases. Also, enhancing refinery operations by measuring, monitoring, and controlling crude oil flow, movement of refined products, and complete fluids process in a refinery.

- Measuring Inventory and Stock: measuring the exact stock of oil and gas in inventory at a particular point of time at the time of production and while being transportation.

- Monitoring Entire Pipeline: Leakages and blasts are the most hazardous outcomes at oil and gas production sites. Flow meter helps in tracking fluid rate of flow and water pressure gauge for pressure and keeping the same under control.

- Monitoring Emission: One of the most crucial aspects of a flow meter is to measure the release of hazardous greenhouse gases and pollutants while extracting and processing crude oil. And reporting the same to keep the environment and air quality from pollutants.

- Enhancing Oil Recovery: Flow meter measures the amount of water and gas to be injected to maximize oil extraction and recovery.

There are many types of flow meters used by the gas and oil production industry ranging from ultrasonic flow meters, mass flow meters, positive displacement flow meters, pressure differentiation flow meters, and velocity flow meters.

3. Pharmaceutical Industry: Flow meters give precise measurement of liquids and gases measurements while manufacturing medicines, drugs, syrups, etc.

Variety of flow meters are used in the pharmaceutical industry to measure a particular type of ingredients in drugs, depending upon the doses, quality, nature of products, severity, handling expertise, and duration of the drug.

- Different Flow meters for different stages: In fact, the use of flow meters at different stages of manufacturing may differ according to the process involved. Like pharmaceutical industries use different types of flow meters at mixing, filtration process, sterilization involves another device type.

- Different flow meters for different fluids: To measure and monitoring the flow of solvents, active pharmaceutical ingredients (APIs), and water for injections (WFIs), liquid flow meters are used. While for gas flow measurements, flow meters regulate different gases like oxygen, nitrogen, carbon dioxide, etc. in the process of fermentation, storage, and finally packaging.

- Reducing waste and cost saving: These pharmaceutical production plants are able to reduce their costs and manage their waste products to a great extent using flow meters in the manufacturing process.

Integration of automated systems with monitoring flow meters in real time, enable these companies to prevent, detect any possible breakage, leakage, or error in the process, and resolve in advance if any arises. All cumulative efforts help in saving costs of production and minimizing waste in the entire process.

Since the pharmaceutical industry is a highly regulated one, there is a requirement of high precision, accuracy, and zero-default scope. To match with all these parameters of accuracy, ability to handle sterilization, and purity, flow meters like electromagnetic, coriolis, ultrasonic, etc. are the top priorities of this industry. All these flow meters adhere to compliance with Good manufacturing Practices (GMPs), Food and Drugs Administration (FDA) approved regulation standards, and other government regulations.

4. Food Beverages Industry: The dependency of flow meters in the food and beverage industry is quite large, to measure the flow of liquids and gases used in manufacturing with precision to avoid any kind of excessive infusion in edible items.

Even items like honey, edible oils and syrups, and other high consistency products also need flow meters for precise filling, packaging, and storing of these products.

- Brings efficiency: Controlling and monitoring the flow of fluids constantly with efficiency in the production processes is what flow meters are responsible for.

Also, play a crucial role in stream flow management, sterilization process, and ensuring optimal healing in the processes. Leading to enhanced product quality, reducing waste production, increasing efficiency, and yielding the perfect results. - Pasteurization and homogenization: Dairy production plants use flow meters to have certain fluid temperature, and flow velocity to manufacture the best quality products.

- Carbonation process: To regulate carbon dioxide (CO2) level in all beverages to maintain the perfect amount of fizz in them, flow meters help immensely.

- Breweries: Flow meter and supply pressure gauge help in measuring flow and pressure of water, malt extract, amount of yeast for fermentation process.

- Providing taste and texture to edible items: Manufacturing of soft drinks, dairy products, beers, preserved food items require a variety of ingredients to be used in a very specific quality to bring taste and texture to food and beverages. At the same time, adhering to the safety and health regulations, installing flow meters in the pipes carrying those fluids is essential.

There are a variety of flow meters used in food and beverages production, some of them are – magnetic flow meter, positive displacement flow meter, coriolis ultrasonic flow meter etc. However, the flow meter usage completely depends upon the properties of the fluids used in the process of production.

5. Power and Energy Generation Plants: Boilers, turbines, and cooling chambers all require flow velocity monitoring in a power and energy generation plant.

And flow meter and supply pressure gauge, ensure that the flow of water is measured, monitored, and regulated in real-time along with pressure under control in the entire pipeline.

These devices (flow meters) are important to ensure safety, operational accuracy, output orientation, precise billing, and efficiency in the complete processes in the energy management industry. Energy production firms use the to measure the rate at which fluids and gases (vapors) in a pipe at a particular time.

- Real- Time Heating and Steam Monitoring: Flow meters measure the steams, water flow, and additional liquids essential in the power and energy generation process. For instance, flow meters are used to monitor heating, boilers, cooling water, and steam turbines in thermal power plants.

- Heating, Ventilation, and Air conditioning (HVAC): Flow meters measure air and water flow in HVAC systems. Ensuring energy efficiency, maintaining system cooling, ensuring balanced airflow, maintaining perfect exhaustion of gases, and optimizing climate control.

Flow meters are very important for power and energy generation plants to have real-time monitoring and optimal energy outcomes at given inputs.

Flow rate calculation:

As discussed above, there are many types of flow meters and their usages depend upon the type of liquid, gas, or vapor (fluids) used. Based on the nature of fluid, the calculation and formulas for calculating flow rate differs, there are some of the formulas for flow testing.

Formula 1:

Q = v * A

Flow Rate of a Fluid (Q) = Velocity of the fluid (v) * Cross- Sectional Area (A)

When only velocity and cross-sectional areas through which the fluid is flowing are give n then we use this formula to calculate fluid flow.

Another way to calculate Flow rate of a fluid:

Formula 2:

Q = V/t

Flow Rate of a Fluid (Q) = Volume of the fluid (V) * Time (t)

When only the volume of the fluid and the time period for the fluid is flowing through the give pipe are given then we use this formula to calculate fluid flow.

Types of Flow Meters

We have been talking about how different industries use different types of flow meters, and have mentioned their names above too. Now, let’s get into a bit of detail about what types of flow meters in the market and how they are different from each other.

- Ultrasonic Flow Meter: These flow meters are primarily used by industries heavily into using gases (some of the gases are hazardous like greenhouse gases). So, at such places, sound waves are used to measure the flow velocity of gases or liquids.

Processes where we can not pause the process to measure the flow rate and gases that should not be contacted directly by human beings, ultrasonic flow meters are the ideal type to opt for. - Differential Pressure Flow Meter: This is the most ancient, most handly, and commonly used method of flow rate measurement. Generally used to measure the pressure drop in a particular area of a pipe through which the fluid is flowing.

Eg- Manufacturing plants, power and energy generation companies, chemical plants, and the oils and gas industry heavily rely on differential pressure flow meters. - Mass Flow Meters: This flow meter calculates the force generated from mass acceleration in a pipe while it carries any kind of fluid in it. Best suited for the industries where processes are more mass-related (for eg. chemical reactions, beverages industries etc.).

Areas like determining material balancing, recipe constructs, billing, and all kinds of custody transfer operations. - Positive Displacement Flow Meter: Used to measure the flow rate and velocity of fluid basis the volume of the fluid or gas by dividing the media (container or pipe) into equal and fixed measured and metered volumes.

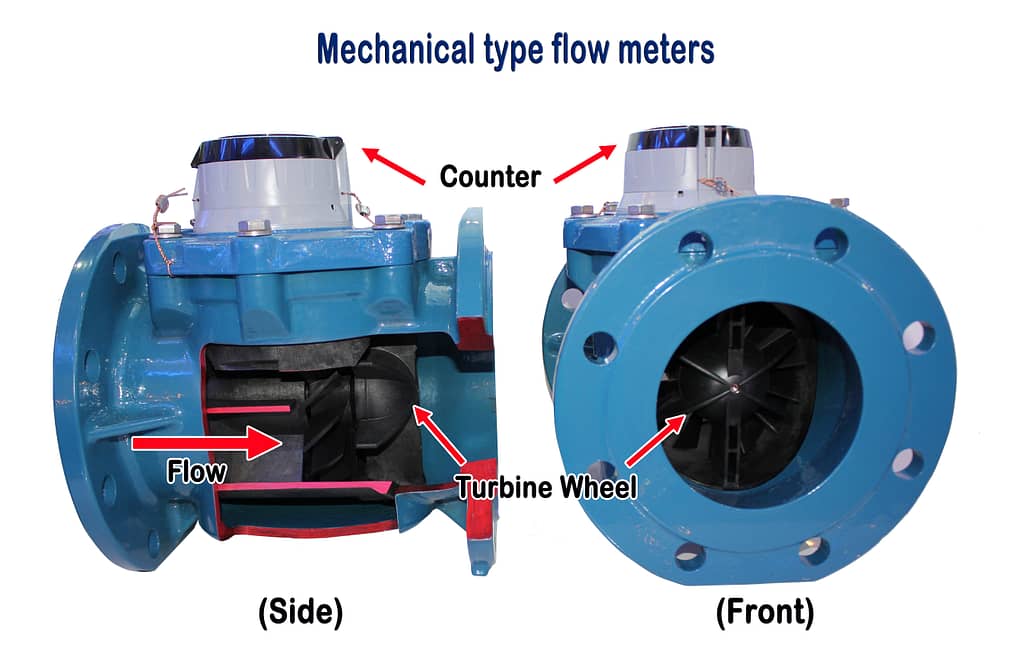

Industries processing petrochemicals, water metering in residential buildings, monitoring and metering gas pipelines, and utility billing all depend on positive displacement flow meters for measuring flow rates and flow velocity. - Turbine Flow Meter: Turbine flow meters use spinning rotors to measure flow rates. Liquid with lower viscosity use this type of flow meters.

Thermal power generating plants use turbine flow meters in their spinning rotors while generating energy or power.

- Thermal Mass Flow Meter: These flow meters use the heat generated in the process to measure flow velocity (the movement of the fluid (gas or liquid) in a pipe given the directions also).

- Coriolis Flow Meter: Where fluids flow via coriolis effect (how earth’s rotation impacts weather patterns and ocean currents). Here the liquid or gas moving through the pipe ( which is a vibrating pipe) distorts the pipe in proportion to the mass flow rate at that time.

- Vortex Flow Meter: Vortex flow meter measures the flow rate of water using vortices, here the liquid pushes an obstruction, leading to creating swirls and forming a vortex to accurately measure the flow velocity.

Water treatment plants, power generation plants using ocean currents to generate energy use this kind of flow meters.

Conclusion

Flow meters are crucial devices used by type industries to measure and monitor flow rates of fluid in pipeline or tubes. These instruments assist in cost reduction and lowering waste generated by monitoring and controlling the flow of liquids precisely.

Whether water treatment plants, pharmaceutical companies, waste management firms, oil & gas companies, or the food & beverages industry, all sectors are using flow meters on a daily basis to ensure effortless operations.

Mark R.

With a strong foundation in industrial safety and fire protection systems, Mark R. specializes in creating clear, technical, and compliance-driven content. Writing for SafeTech Reports, he covers topics such as fire hydrant testing, PPE protocols, emergency procedures, and smart technology integration in safety systems. His work ensures that professionals stay informed on the latest regulations, best practices, and emerging trends in safety and infrastructure maintenance.

Get in touch

We usually respond within 24 hours

Need Reliable Water Flow Test Equipment?

For over 70 years, New England Manufacturing has been the trusted source for fire hydrant and water flow testing kits. From pitot gauge kits to custom test kits, we provide precision, durability, and expert calibration to meet your needs.

- Custom-built test kits

- High-quality pressure gauges

- Reliable calibration services